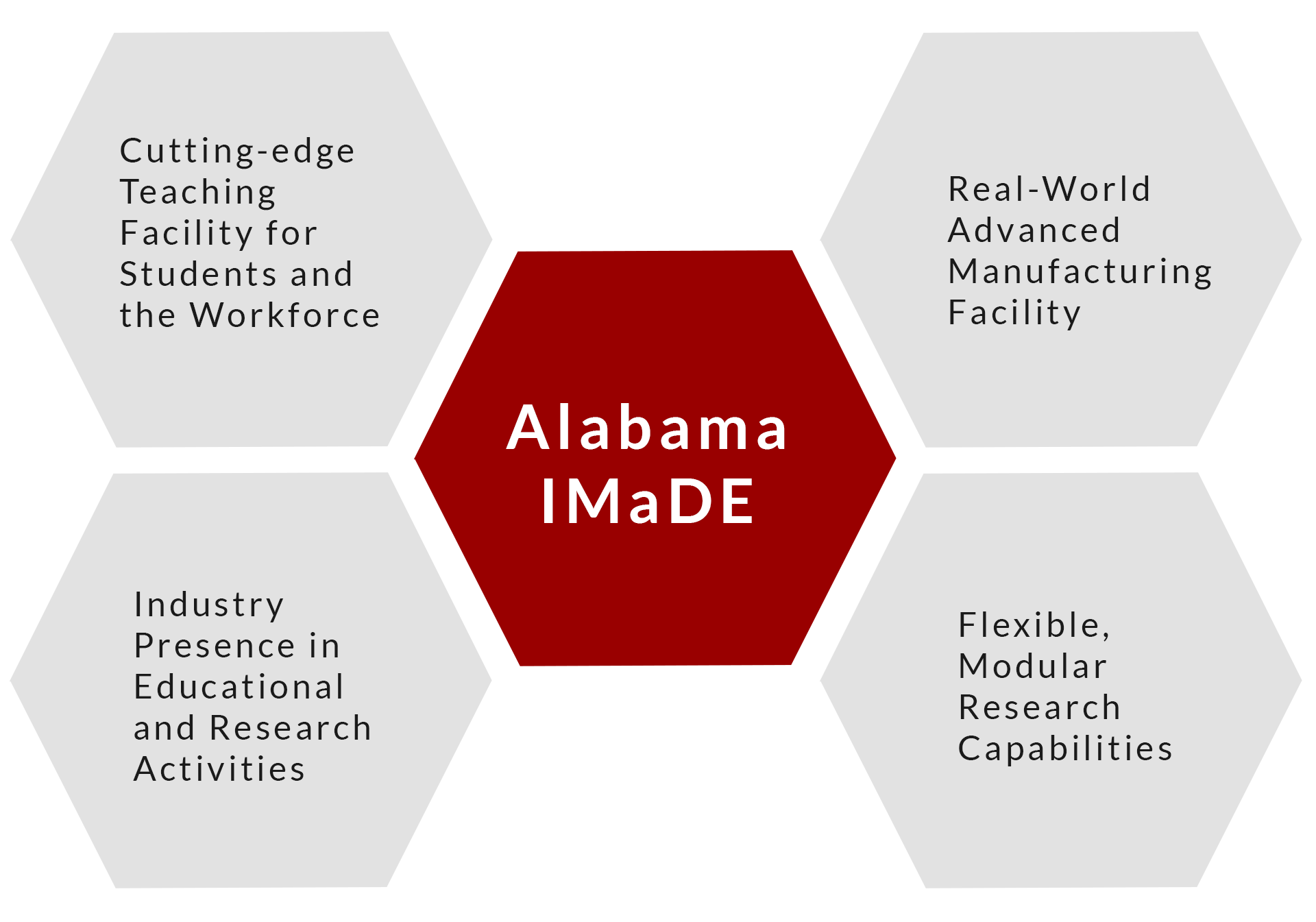

Alabama IMaDE

The Premier Hub for multidisciplinary research and education in intelligent and advanced manufacturing systems and processes.

The Alabama Initiative on Manufacturing Development and Education (Alabama IMaDE) establishes the modernization of manufacturing technology, techniques, and workforce education as a new focal point at The University of Alabama.

Central to this initiative, is a new facility supporting these objectives and housing state-of-the-art advanced manufacturing technology, educational and research laboratories, classrooms, and services.

Alabama IMaDE Mission Statement

The mission of Alabama IMaDE is to address the future of industrial problems through education, research, and service with a systems integration and industry mindset approach. The initiative will produce broadly educated students with a wide range of career opportunities centered on the future of manufacturing and will cultivate an American workforce to lead the global manufacturing sector through the fourth industrial evolution and beyond.

Teaching and Training Facility

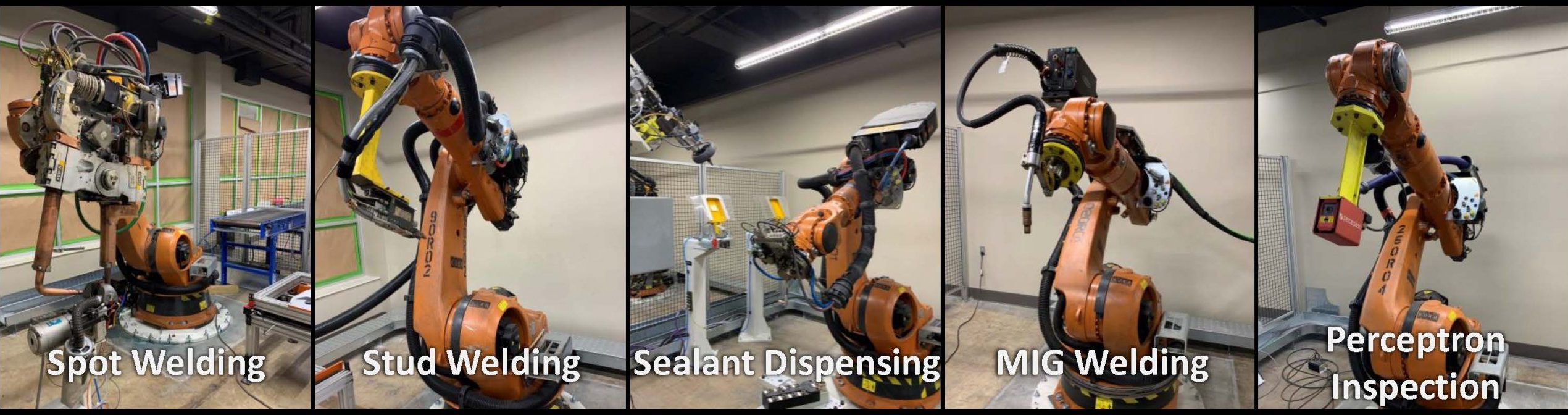

Directly adjoined to the primary manufacturing facility, a new educational facility enables combined classroom and hands on project based learning in manufacturing systems taught on real world industrial robotic manipulators and software as well as programming, operating, and implementing automation systems such as programmable logic controllers.

This space supports the developing manufacturing systems engineering program at The University of Alabama, provides a location for technical and educational research, and enables on campus workforce development training in cooperation with industrial partners.

Flexible and Modular Research Capabilities

Reconfigurable, modular, and state of the art manufacturing research facilities such as the Advanced and Intelligent Manufacturing Systems Lab are capable of producing theoretical and applied research addressing the needs and challenges of the increasingly advanced, intelligent, and robot based manufacturing industry.

Research Applications

Interdisciplinary and transdisciplinary application domains of interest include automated manufacturing; health monitoring through identification; safe, efficient collaborative and robot based manufacturing; agile and reconfigurable robotics; and applications of integrated virtual, augmented, and mixed reality in manufacturing.

The world is on the edge of another industrial revolution, and Alabama’s manufacturing economy is on the rise. There are more than 265,000 manufacturing jobs across the state which account for almost 20% of all jobs in the West Alabama.

Through Alabama IMaDE’s focus on advanced manufacturing and industry 4.0, The University of Alabama will provide unmatched workforce development opportunities for Alabama’s current and future industry through industrial partnerships, industry guided training modules, and the coordinated transition of innovative research products to our educational curricula.

MAJOR ACTIVITIES UNDER Alabama IMaDE

Innovating Educational, Research, and Career Pathways:

Alabama IMaDE will provide unmatched integration of educational, research, and career pathways in cutting-edge industry-relevant manufacturing principles, technologies, and management techniques to

- University students.

- Local/national/global industry.

- The existing regional workforce.

- The future workforce.

Modular Courses in Advanced Manufacturing

As part of Alabama IMaDE, UA is currently developing a selection of modular courses that will provide targeted training in various Advanced Manufacturing skillsets to university students and industry professionals alike. Each of these courses, designed as 5-week curricula, will review critical topics in today’s advanced manufacturing environment and utilize real-world equipment for project-based learning at levels that span fundamental, intermediate, and advanced materials.

Proposed Courses

- Basics of Robotics

- Basics of PLC

- Basics of Automation and Materials Handling

- Robotic Welding

- Flexible Manufacturing Systems

- Industrial Robotics

- Industrial Automation and Control

- Instrumentation for Robots

- Process Monitoring and Control

- Introduction to Industrial Management

- Introduction to Industrial Internet of Things

- Introduction to Industry 4.0

- Advanced PLC

- Advanced Robotic Welding

- Automation and Materials Handling II

Fostering Innovation for Industry 4.0 and Advanced Manufacturing:

Alabama IMaDE will foster a new innovation centric culture and infrastructure that leverages and supports the region’s vital manufacturing sector. Programs under this initiative will cultivate novel application driven intellectual property and manufacturing centric startups while establishing unique communication and networking channels between industry, academia, and innovators. Alabama IMaDE will enhance the academic experience at The University of Alabama with project based learning, real world regional case studies, and opportunities for internships, cooperative education, and employment at the frontier of the emerging manufacturing sector through and beyond industry 4.0.

Industry 1.0

Steam, Hydraulics, and Mechanical Power Transmission

Industry 2.0

Electrical Power, Mass Production, and Assembly Lines

Industry 3.0

Computer Aided Manufacturing, Automation, and Robotics

Industry 4.0

Cloud Computing, Connected Factories, and Autonomy

Pragmatically, the development of this culture and infrastructure will grow the regional manufacturing economy by introducing new start-up businesses, increasing employment opportunities in the manufacturing sector, generation new manufacturing-centric IP, and attracting entrepreneurial and manufacturing talent and investment to the region.

UNIVERSITY-LEVEL ACTIVITIES

Revolutionizing Additive Manufacturing and Repair:

Researchers at The University of Alabama are developing, demonstrating, and applying innovative computational modeling methods and design concepts for cost-effective, accurate, and safe manufacturing and repair methodologies for transfer to public and private stake-holders for implementation.

Incubating Novel Manufacturing Concepts and Start-Ups:

Through the development of a new innovation and entrepreneurship incubator, The University of Alabama will create an agile, collaborative, and innovative environment for the maturation and demonstration of advanced manufacturing technologies, education, and local industry needs.

Reinforcing the Manufacturing Workforce:

Consistent with the educational and outreach activities through Alabama IMaDE, The University of Alabama is working to grow existing and initiate new collaborations between government, industry, and academia through public – private partnerships, while promoting STEM and workforce development.

Generating new Manufacturing Technologies:

Through Alabama IMaDE, students and researchers at The University of Alabama will lead the way in the integration of multiple, cutting edge technologies and processes, demonstrating significant improvement in manufacturing producibility, affordability, and repeatability.

Ways to Get Involved!

Expertise:

- Share experience through seminars and guest lectures.

- Teach our modular courses or provide consultation on course contents.

Research Collaboration:

- Work with UA researchers, students, and facilities to perform R&D, prototyping, etc.

Equipment and Services:

- Assist in the installation, maintenance, or modernization of educational equipment.

Endowed Professorships in Advanced Manufacturing Systems:

- Attract top-tier faculty to perform advanced manufacturing systems research and education at The University of Alabama.

- Grow Industry 4.0 and IIoT as a focal point at UA.

Endowed Scholarships and Fellowships:

- Initiate scholarship programs for talented undergraduate MSE students.

- Provide fellowship opportunities and experiential learning for UA graduate students.

Named Buildings and Labs:

- E.g., name the advanced manufacturing facility or all of Alabama IMaDE.

Industries/Companies Supporting

Mercedes-Benz U.S. International, Inc.

Honda